If you want to choose a PP hollow board extrusion line that suits you, you must first understand your own production requirements and product characteristics. If you are an extrusion product manufacturer, you need to choose a suitable PP hollow board extrusion line. First of all, you need to understand your production requirements and product characteristics. Then, according to these requirements and characteristics, choose the PP hollow board extrusion line that suits you.

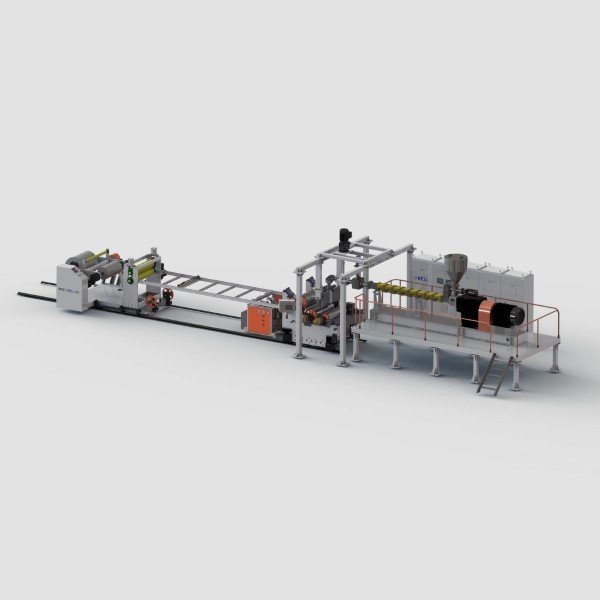

Hollow sheet extrusion production line is suitable for producing hollow sheets of various specifications, special screw structure, control of process parameters, stable shaping equipment, and precise temperature control system. Electronic control equipment effectively optimizes the operation of the entire line to achieve high quality and high output.

Through the machine, using high-voltage and high-frequency waves, the shock molecules are ejected from the nozzle. The molecular structure is destroyed by the electric shock and penetrates into the surface of the printed matter, so that the surface of the printed matter can increase adhesion and can be coated or printed.

PP hollow profiles have the characteristics of non-toxic, 100% recycling, light weight, low temperature resistance, waterproof and moisture proof, corrosion resistance, impact resistance, energy absorption, sound insulation and so on.

Widely used in building lightweight partitions, building material protection boards, aquatic vegetable and fruit packaging boxes, turnover boxes and other packaging. In addition, PP hollow board has bright colors, can be printed and processed, and is also widely used in stationery, card supplies, etc.

one. What is PP hollow board extrusion line?

PP hollow board extrusion line is a kind of production equipment used to produce pp hollow board. Through this equipment, the pp material can be filled into the hollow board, and then the pp material can be extruded to the surface of the hollow board by an extruder, thus forming a pp hollow board. Hollow board extrusion production line is a production line that uses hollow board technology to press plastic particles into hollow boards and then cut them into many small pieces.

PP hollow board extrusion production line mainly consists of extrusion unit, hollow fiber membrane module and PP hollow board special forming machine, etc. PP hollow board is a kind of high-density polyethylene plastic film made of PE as raw material, which is non-toxic , good transparency, high light transmittance, good anti-ultraviolet radiation performance, strong chemical stability, high mechanical strength, convenient processing, long service life, low overall cost, and wide application.

The main products of the PP hollow board extrusion line are: hollow board, hollow fiber membrane and special resin products for PP hollow board.

Features of PP hollow board extrusion production line: 1. Adopt fully automatic continuous production process. The main engine adopts international advanced equipment, which can realize fully automatic production. 2. Hollow panels of different sizes can be customized according to customer needs, and various special resin products can be produced as a complete set. 3. The equipment occupies a small area, with high production efficiency, short production cycle and stable product quality. 4. With the double-shaft stirring structure, the material flows faster and the stirring uniformity is higher.

two. Why choose PP hollow board extrusion line?

There are many reasons to choose PP hollow board extrusion line, mainly including the following points:

- PP hollow board extrusion production line can effectively use resources, reduce waste and energy consumption.

- The PP hollow board extrusion production line has simple process and is easy to operate and maintain.

- The PP hollow board extrusion production line has high output and can quickly produce large quantities of products.

- The PP hollow board extrusion production line is of good quality and the product has excellent performance.

three. How to choose the PP hollow board extrusion line that suits you?

To choose the pp hollow board extrusion line that suits you, you need to consider many factors, such as output, cost, product characteristics, etc. The following is an introduction to the key factors for choosing a PP hollow board extrusion line.

- Output requirements

Output is one of the important considerations in choosing a PP hollow sheet extrusion line. According to your production requirements, you can choose different specifications of the production line.

- Select the corresponding production line according to the thickness and molding needs of PP hollow board.

- Select the appropriate production line according to the size and form of the PP hollow board.

- Select the appropriate production line according to the quality and use needs of PP hollow board

This production method has the following advantages:

- Low energy consumption: During the production process, there is gas between the plastic particles, so the power consumption can be reduced.

- Good quality: The hollow board extrusion line can produce high-quality products.

- No noise: Since the hollow board extrusion line does not generate noise, it can work in the production area.

- High efficiency: The hollow sheet extrusion production line has high efficiency and can quickly produce a large number of commodities.

Pressekontaktdaten:

Tel: +86 18861956208

Email:cindy@gwell.cn

Tel: +86 18861956208

Email: zl@gwell.cn

China Gwell Machinery Co., Ltd.

Room 1519, 15th Floor

No. 89 Jilong Road

Free Trade Area

Shanghai City,China